Warehouse Racking and Storage

Your success starts with racking. And our expertise.

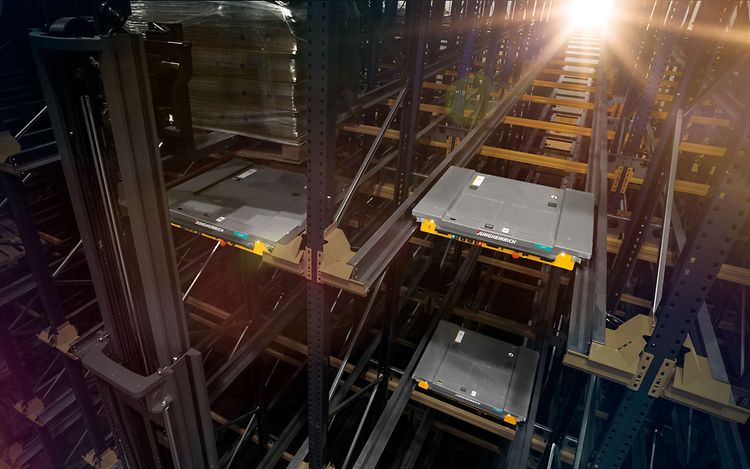

For 70 years, we have been developing customised, high-quality solutions. In close collaboration with you, we design a racking concept tailored to your requirements: from storing pallets and containers to trays, cartons, and long goods. We take a holistic view of your warehouse, incorporating every aspect from fleet management to warehouse management software. This way, your racks become the backbone of a successful future.

Robustly constructed racks are essential for the secure and organised storage of various goods. In these sturdy heavy-duty racks, you can store loads of up to several tons, depending on the model. Whether for use in industry, logistics, or production, we at Jungheinrich assist you with individual warehouse planning and offer a wide portfolio of high-quality industrial racks for every need. Learn more here and buy the right warehouse racks for efficient warehouse logistics!

Customised warehouse equipment for improved efficiency and safety

Professional warehouse equipment with the right racking system creates order in the warehouse, facilitates workflows, and protects both the stored goods and the employees from damage. There are no restrictions on the types of goods and materials that can be stored, as long as the goods are properly packaged and secured and the load capacity of the storage structure is not exceeded.

Choosing the right type of rack is crucial to ensuring risk-free daily operations. Jungheinrich offers various types of racks, each varying in layout, construction, size, and load capacity. Pallet racks are particularly common. They are specifically designed for storing palletised goods, which can be loaded and unloaded using high-lift trucks or forklifts, or picked with rack-servicing devices.

The following racking solutions are available from Jungheinrich:

Pallet racks

Racks for small-parts storage

Long-goods racks and mezzanine floors

Racking systems as complete solutions

What is the Pallet Racking?

Pallet racking, commonly referred to as racking, is essential equipment for storing products on pallets within a warehouse or distribution center. There are several types of pallet racking systems available to meet various needs and objectives, including selective, double-deep, and drive-in racking. To enhance the efficiency of your warehouse storage, pallet racking is an ideal solution. Selecting high-quality racks is crucial, as they form the foundation of your warehouse. Quality racks ensure operational success, increase efficiency, reduce picking times, improve stock accuracy, and optimize warehouse space. When choosing pallet racking, it's important to prioritize material quality and select racks that come with a guarantee of product quality. This careful selection process is fundamental to creating an efficient and effective warehouse operation.

Does your business need racking?

If you're unsure whether racking is necessary for storing your products, here are some key reasons and reference information to help you decide:

- Stocking Products and Managing Inventory: Racking systems can organize products into groups for easy access, which can significantly benefit inventory management.

- Optimizing Warehouse Space: For businesses with a large volume of products, racking systems facilitate efficient product arrangement and transportation, optimizing the use of available space.

- Storing Different Sizes of Carton Boxes: Adjustable racking systems are helpful for accommodating various box sizes, making them ideal for storing different sizes of carton boxes.

- Storing Long and Large Materials: For items such as tubes or wires, cantilever racking is ideal. It simplifies the storage, picking, and transport of these specific products.

Always there for you: Racking inspection of your warehouse system

Jungheinrich continues to support you even after the purchase of a racking system with comprehensive services. Damaged storage equipment poses risks to your employees, vehicles, and stored goods. During a racking inspection according to European standard DIN EN 15635, our experts ensure that all calculable risks are eliminated. The qualified expert inspection of your warehouse racks includes annual inspections during ongoing operations, repairs using original spare parts and inspection sticker according to normative requirements.

How to Select the Best Racking for Your Warehouse

When considering racking for your warehouse, it's crucial to understand your warehouse's limitations and requirements. Choosing the wrong racking system can lead to operational inefficiencies and safety issues. Here are key factors to consider before purchasing racking:

- Assess Your Inventory Needs: Evaluate the types of products you store, including their sizes, weights, and quantities. Different products may need specific racking solutions, such as cantilever racking for long items or selective racking for varied inventory.

- Space Utilization: Analyze your warehouse layout and available space. Measure the floor area, ceiling height, and note any obstructions. Opt for racking systems that maximize vertical and horizontal space, like double-deep or pallet flow racking for high-density storage.

- Accessibility Requirements: Consider how frequently you need to access your inventory. For frequent access, selective racking provides direct access to each pallet. For less frequent access, drive-in/drive-through or push-back racking might be more suitable.

- Inventory Management: Decide on your inventory rotation method. For first-in, first-out (FIFO) management, pallet flow racking is ideal. For last-in, first-out (LIFO) management, push-back racking may be a better fit.

- Load Capacity: Ensure the racking system can support the weight of your products. Verify the load capacity of the racking to avoid safety hazards and ensure it meets your requirements.

- Flexibility and Scalability: Choose a racking system that can be easily adjusted or expanded as your business grows. Look for adjustable racking systems and modular designs that offer flexibility for future changes.

- Types of Forklifts in Use: Warehouses in industrial plants regularly use forklifts to move goods. The type of forklift varies by warehouse and includes electric forklifts, VNA (Very Narrow Aisle) forklifts, and AGV (Automated Guided Vehicle) forklifts. When selecting a racking system, it's crucial to consider its compatibility with the specific forklifts used in your warehouse to ensure efficient and safe operations.

- Safety Considerations: Prioritize safety features such as sturdy construction, secure fastening, and proper load distribution. Ensure the racking system complies with safety regulations and industry standards.

- Budget: Consider your budget for both initial installation and ongoing maintenance. Compare the costs of different racking systems and choose one that provides the best value for your investment.

- Operational Efficiency: Evaluate how the racking system will impact your warehouse operations. Select a system that enhances workflow, reduces handling time, and improves overall efficiency.

- Consult Experts: Seek advice from racking specialists or warehouse consultants. They can provide insights and recommendations based on your specific needs and help you make an informed decision.

By considering these factors, you can select the best racking system for your warehouse, ensuring efficient and safe operations.

Why Jungheinrich Racking?

Racking is a crucial component for industrial growth. At Jungheinrich, a leader in intralogistics systems, we specialize in planning and building efficient racking systems. Our solutions adhere to internationally certified standards, ensuring optimal performance. Our experts provide comprehensive support from the planning stage to after-sales service. Additionally, if you're interested in electric forklifts, electric reach trucks, or other types of forklifts for warehouse operations, Jungheinrich can seamlessly integrate forklift and racking solutions to maximize production capacity and efficiency.